Discover the Top Industrial Coffee Grinder for Commercial Use

Wiki Article

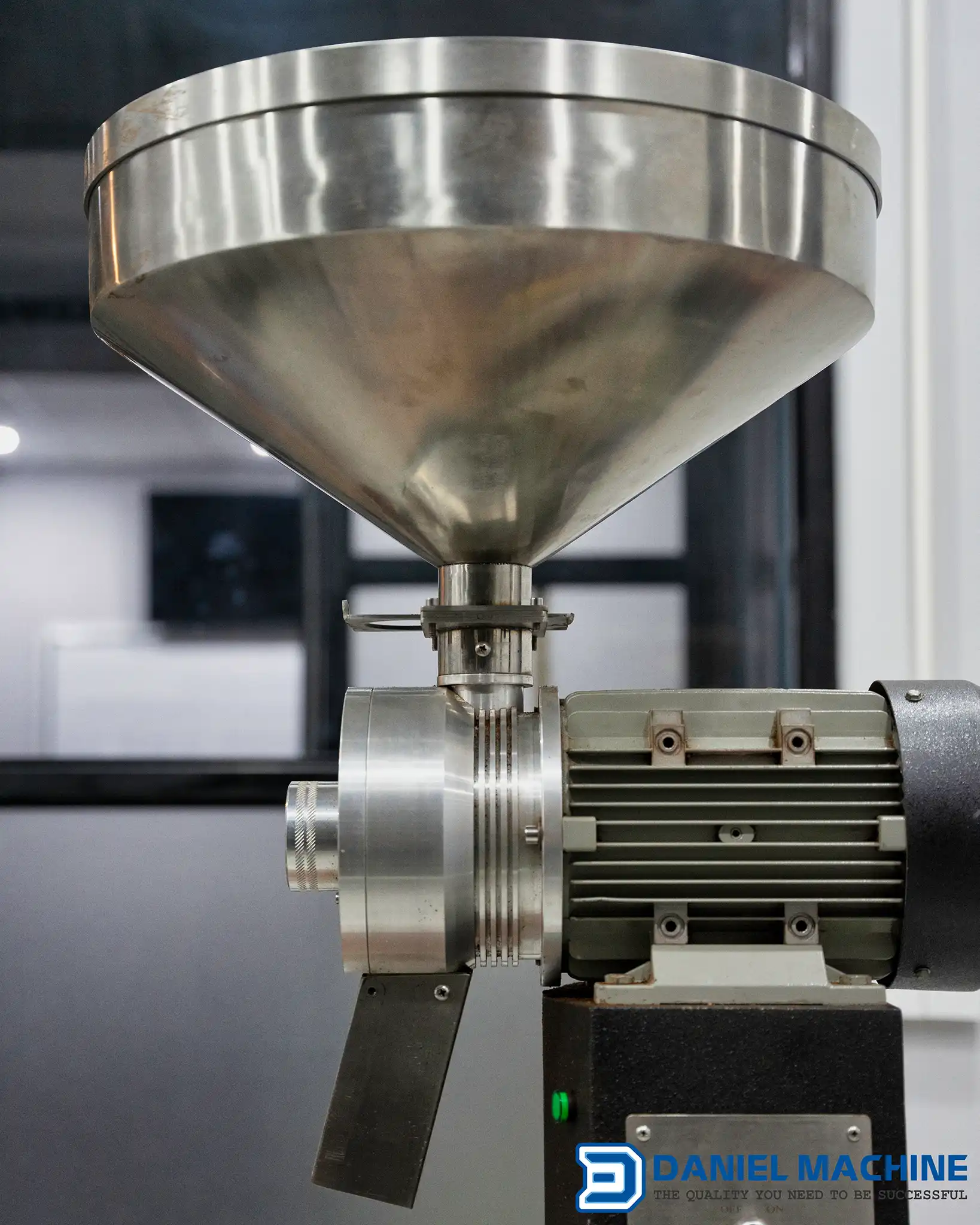

Industrial Coffee Mill Overview: Boost Effectiveness and High Quality

In the affordable landscape of coffee production, choosing the right commercial coffee mill plays a critical function in boosting both effectiveness and item high quality. Understanding the nuances of numerous grinder kinds and essential features-- such as personalized grind settings and robust construction-- can dramatically affect the final flavor account of the coffee.Recognizing Grinder Types

When picking a commercial coffee mill, understanding the numerous kinds available is critical for optimizing both taste removal and operational effectiveness. The 2 primary sorts of grinders are blade mills and burr grinders. Blade grinders make use of sharp blades that chop coffee beans into irregular dimensions, causing irregular extraction and potentially undesirable tastes. While blade grinders are frequently extra economical and ideal for small procedures, they are typically not suggested for commercial usage.

Ultimately, choosing the right sort of grinder is important to maintaining high quality and performance in coffee manufacturing, making it critical for organizations to invest in premium burr mills for optimal results.

Trick Attributes to Consider

Choosing a commercial coffee mill calls for careful factor to consider of several crucial attributes that can significantly influence both efficiency and the general coffee experience. Among the primary elements to examine is the grinding system. Burr grinders are usually liked over blade grinders, as they give a constant grind size, which is vital for optimal removal and taste.An additional essential attribute is the grinder's capability. A versatile mill with numerous setups permits you to tailor the work size to various developing techniques, boosting the coffee's taste profile.

The building and construction material likewise plays a role in durability and upkeep. Stainless steel parts frequently offer durability and are less complicated to clean up, which is vital for keeping hygiene criteria. Evaluate the grinder's sound degree, specifically in a busy café or manufacturing setting, where too much sound can be turbulent. Purchasing a mill that stabilizes these features can greatly improve both functional efficiency and the quality of the coffee served.

Optimizing Grinding Process

To attain the finest outcomes in coffee prep work, maximizing the grinding procedure is vital. The grind size substantially affects extraction, flavor, and total quality of the made coffee.

In addition, checking the grinding speed can optimize the process. Slower grinding commonly produces much less warm, maintaining fragile flavors and aromas. Alternatively, faster grinding might produce too much heat, adversely affecting the coffee's top quality.

Maintenance and Care Tips

Appropriate upkeep and treatment of commercial coffee grinders are vital for making sure optimal efficiency and long life. Regular cleaning is the structure of maintenance; residue build-up can influence taste and grinding performance. It is advisable to clean up the grinder after each usage, wiping down the outside and getting rid of any coffee grounds from the burrs.In addition, inspect the grinding burrs for deterioration. Dull burrs can endanger grind uniformity, so they need to be changed as needed. Industrial Coffee Grinder. Regularly adjusting the grinder is additionally vital, as this preserves the preferred grind dimension for various brewing approaches

Lubrication of relocating components ought to be executed according to the manufacturer's specifications, as this decreases rubbing and extends the life of the tools. It is important to utilize food-grade lubricants to guarantee you could try this out safety and security and compliance with health and wellness regulations.

Finally, maintain the grinder in a dry and steady atmosphere to avoid corrosion and corrosion. By adhering to these upkeep and care pointers, operators can visit this website boost the effectiveness of their industrial coffee grinders while guaranteeing high-grade outcome and prolonged functional life.

Return on Investment Analysis

Evaluating the roi (ROI) for industrial coffee grinders is vital for companies seeking to optimize their coffee manufacturing abilities. A thorough ROI analysis aids figure out the financial viability of buying high-quality mills, permitting services to consider the initial expenses versus prospective gains.To perform an extensive ROI analysis, companies must think about numerous vital factors. First, examine the acquisition rate of the mill, including installment and any type of needed modifications to existing infrastructure. Next off, calculate operational costs, including energy usage, upkeep costs, and labor effectiveness improvements. High-performance mills typically bring about lowered grinding time and raised throughput, which can substantially enhance efficiency.

Furthermore, take into consideration the impact on item top quality. Industrial useful content Coffee Grinder. Superior grinders yield an even more constant work size, which can enhance flavor accounts and client satisfaction, ultimately driving sales. By increasing the high quality of the end product, businesses can validate greater rates, resulting in raised profits

Conclusion

In summary, an industrial coffee grinder plays a pivotal role in boosting both performance and item high quality within coffee production. By selecting high-quality burr mills furnished with crucial functions such as adjustable grind setups and resilient building and construction, businesses can ensure ideal flavor extraction. Moreover, regular upkeep is important for sustaining grinder efficiency and maximizing consumer fulfillment. Ultimately, the calculated financial investment in a reputable mill adds dramatically to improved earnings and competitiveness in the coffee sector.In the affordable landscape of coffee manufacturing, picking the best commercial coffee grinder plays a crucial role in improving both effectiveness and item quality. The two key kinds of mills are blade mills and burr mills. Within the burr grinder classification, there are flat burr mills and conical burr mills, each with its benefits. Burr mills are generally favored over blade mills, as they give a constant grind dimension, which is vital for optimum removal and flavor.

In recap, an industrial coffee grinder plays a critical role in enhancing both performance and item top quality within coffee production.

Report this wiki page